When it comes to selecting the right gearbox for your industrial applications, understanding the various types available is crucial. Each type—be it spur, bevel, worm, or planetary—offers unique benefits tailored to specific needs. You might find that a helical gearbox suits your quiet operation requirements, while a worm gearbox could provide the torque you need in tighter spaces. As you consider these options, think about how each could impact your efficiency and performance. But which gearbox will ultimately meet your demands? Let’s explore further to uncover the best fit for your operations.

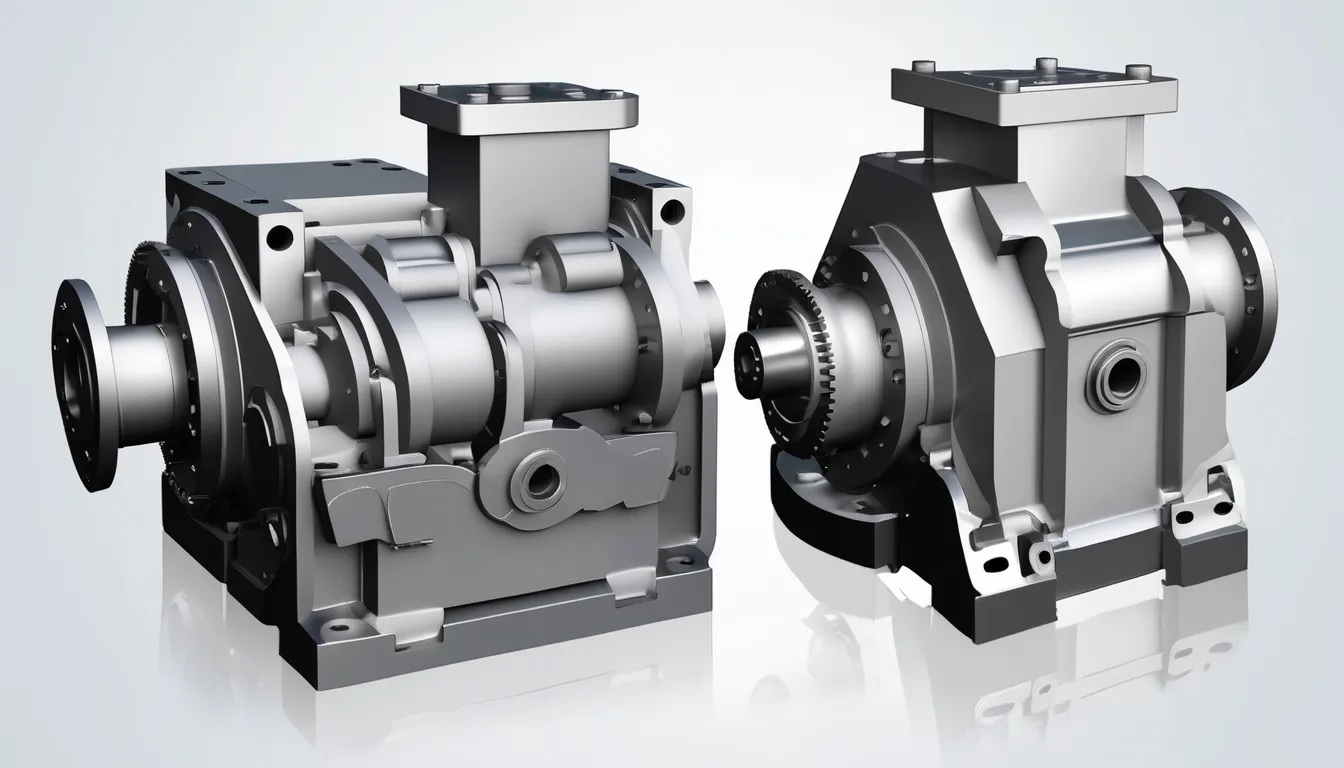

Overview of Gearbox Types

When you’re diving into the world of gearboxes, it’s essential to sort through the various types available. Each type has its unique features and applications, ensuring you find the right fit for your project.

First, you’ll encounter helical gearboxes. These are known for their smooth operation and high efficiency, making them ideal for applications that require quiet performance.

Then, you’ve got worm gearboxes, which offer high torque in a compact design. Their ability to provide significant speed reduction is perfect for heavy machinery.

Next up are bevel gearboxes, which allow for a change in shaft direction. They’re commonly used in applications where space is limited but you still need power transfer.

Planetary gearboxes are another popular choice, known for their ability to handle high loads and offer a compact design.

Lastly, you might consider cycloidal gearboxes. They provide high torque and efficiency, making them suitable for applications with high shock loads.

Understanding these types will help you make informed decisions about which gearbox aligns best with your needs. Be sure to weigh your options carefully, as the right gearbox can significantly impact your system’s performance.

Spur Gearboxes

Spur gearboxes are frequently favored for their simplicity and effectiveness in power transmission. They consist of parallel shafts with gears that mesh directly, making them straightforward and efficient. When you need a reliable solution for transferring motion and force, spur gearboxes are often your best bet.

One of the key advantages of spur gearboxes is their high efficiency, typically ranging around 95% or more. This means you’ll lose minimal energy as heat, which is crucial for maintaining operational efficiency. Additionally, their design allows for easy manufacturing and maintenance, saving you both time and resources.

When you’re considering gear ratios, spur gearboxes provide versatility. You can achieve various output speeds and torque levels just by changing gear sizes. This adaptability makes them suitable for a wide range of applications, from conveyor systems to robotics.

However, it’s important to keep in mind that spur gearboxes can generate noise due to the direct contact of gears. If noise reduction is a priority for your project, you might want to explore additional options.

Bevel Gearboxes

Bevel gearboxes are essential components in many mechanical systems, designed to transmit power between shafts that are not parallel. They’re particularly useful in applications where space is limited or when a change in direction of the shaft’s rotation is needed. You might encounter bevel gearboxes in various industries, including automotive, aerospace, and manufacturing.

One of the key advantages of bevel gearboxes is their ability to handle high torque loads while maintaining efficiency. Here’s a quick comparison of common bevel gearbox types:

| Type | Efficiency (%) | Application |

|---|---|---|

| Straight Bevel | 95-98 | General power transmission |

| Spiral Bevel | 90-95 | High-speed applications |

| Hypoid Bevel | 85-90 | Heavy-duty machinery |

When selecting a bevel gearbox, consider factors like load capacity, speed, and the specific orientation of your application. By choosing the right type, you can ensure optimal performance and longevity for your mechanical system. Bevel gearboxes may seem straightforward, but their impact on efficiency and power transmission is significant.

Worm Gearboxes

Worm gearboxes offer a unique solution for power transmission, particularly when a high gear reduction and compact design are needed. They consist of a worm (a screw-like gear) and a worm wheel (a gear that meshes with the worm). This configuration allows for significant torque multiplication and a smooth operation, making them ideal for applications like conveyors and winches.

One of the main advantages you’ll find with worm gearboxes is their ability to achieve high reduction ratios in a single stage. This means you can reduce the input speed dramatically while increasing torque. Additionally, the non-reversible nature of worm gearboxes provides a locking mechanism that prevents back-driving, which is beneficial in certain applications.

However, keep in mind that they can be less efficient than other types of gearboxes, often resulting in more heat generation. Proper lubrication is crucial for maintaining performance and prolonging lifespan.

When selecting a worm gearbox for your project, consider the load requirements, desired speed, and efficiency levels. Overall, they’re a reliable choice when you need compact, high-torque solutions in your industrial setups.

Planetary Gearboxes

Planetary gearboxes are renowned for their compact design and high efficiency, making them a popular choice in applications requiring precise speed and torque control.

These gearboxes consist of a central sun gear, multiple planet gears, and a ring gear, all working in unison to deliver remarkable performance.

When you choose a planetary gearbox, you’ll experience benefits like:

- Increased torque output: They can handle heavy loads without compromising performance.

- Space-saving design: Their compact form fits into tight spaces, making installation easier.

- High efficiency: You’ll enjoy minimal energy loss, ensuring your system runs smoothly.

- Durability: Built to last, these gearboxes withstand wear and tear, minimizing maintenance costs.

- Versatility: They’re perfect for various applications, from robotics to conveyors.

Conclusion

In summary, understanding the different types of gearboxes is crucial for optimizing your industrial applications. Whether you choose a spur gearbox for simplicity, a bevel gearbox for angled drives, a worm gearbox for compact torque, or a planetary Industrial Gear Drive for high efficiency, each option has unique benefits tailored to specific needs. By selecting the right gearbox, you’ll enhance performance and efficiency, ensuring your operations run smoothly and effectively. So, make an informed choice for your next project!